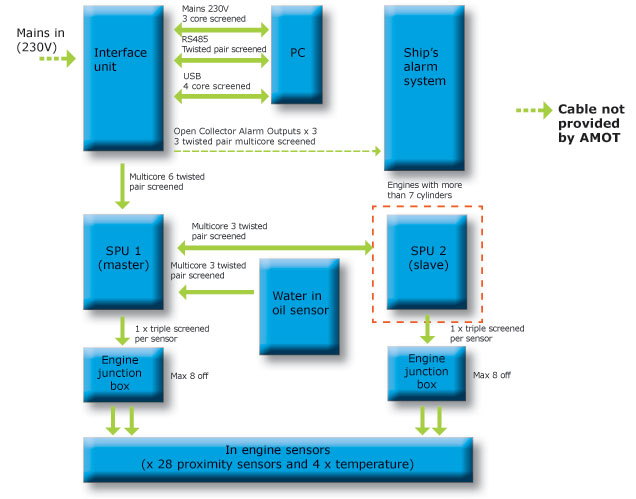

XTS-W+ bearing condition monitoring system interconnectivity

Overview of system components

Proximity sensors |

The proximity sensors are robust, proven electronic sensors, which use a low intensity electromagnetic field to detect the position of the guide shoes at bottom dead centre (BDC). The sensors are fixed to custom designed brackets for different engine types. | |

Water in oil sensor |

The water in oil sensor monitors moisture content in the engine’s lubricating oil. | |

Engine junction box |

Engine junction boxes fit to the outside of the engine. These allow cables passing through the wall of the engine to be removed for servicing if required. | |

Signal processing unit (SPU) |

The Signal Processing Unit is capable of simultaneously processing signals from up to 14 proximity sensors, four temperature sensors and one water in oil sensor. | |

Interface unit |

The Interface Unit houses an Uninterruptible Power Supply (UPS) and an 18V DC power supply. In addition, it provides a means of connecting the alarm signals to the ship control and alarm system. |